Gear ratio calculator teeth

Some important features of gears and gear trains are. For example if the pinion gear has 41 teeth and the ring gear has 11 teeth the ratio would be calculated as 4111 which is equal to 373 3731.

The Ultimate Dirt Bike Sprocket Gearing Guide Dirt Bike Bike Pit Bike

A very common mini bike ratio is 11-12 teeth on the clutch and 72 teeth on the axle sprocket.

. Unless driven gears with more than 45 teeth and or drive gears with fewer than 15 teeth become available it will be impossible without using a ratio adapter to have an accurate speedometer with rear end gear ratios lower higher numerically than 4101. Calculate gear ratio by dividing the number of teeth on the driven gear by the number of teeth on the driving gear. Maximum number of teeth increased to 400.

For example a 373 gear ratio requires 373 driveshaft rotations to turn your tires once around. It is possible to design gear teeth for gears that are non-circular yet still transmit torque smoothly. J l Load Inertia lb-in-sec 2.

NUMBER OF TEETH - FIRST GEAR. T l Torque of Load lb-in. You should be able to find your gear ratio listed on the axle tag however if that has gone missing you can simply count the number of teeth on each gear and divide the number of ring gear teeth by the number of pinion gear teeth.

For the purposes of this example well treat the driver gear as having 80 teeth and a rotation rate of 100 rpm. A go-kart with an engineclutch sprocket 12 teeth and a rear axle sprocket 75 teeth has a gear ratio of 625 or 6251. For example if the sun gear has 20 teeth and the ring gear has 60 the planetary gear has 80 teeth.

Find the ratio of the driver gear and. The range is from 50 to 110 teeth. Thursday 28 June 2012 1032 Subject.

We built this gear measurement over pins calculator as. The driver gear is the gear connected to a motor or other power source usually by an axle. Graphical gear calculator for bicycle gearing systems.

The number on the driven gear housing must match the number of teeth on the driven gear. Top Speed and Gear Ratio Calculator Enter Parameters Below Motor Speed. Fixed DXF file format.

Worm gears are grouped into two general classes fine-pitch worm gearing and coarse-pitch worm gearing. A gear train is a mechanical system formed by mounting gears on a frame so the teeth of the gears engage. Calculator Gear Ratio Guide.

Skz reaction to you being sick. 1 Fine-pitch worms and worm gears are generally used to transmit motion linear or. The Spicer Gear Ratio Calculator will assist you in determining the ratio between the ring gear and pinion gear in the differential housing in the rear end axle of a vehicle.

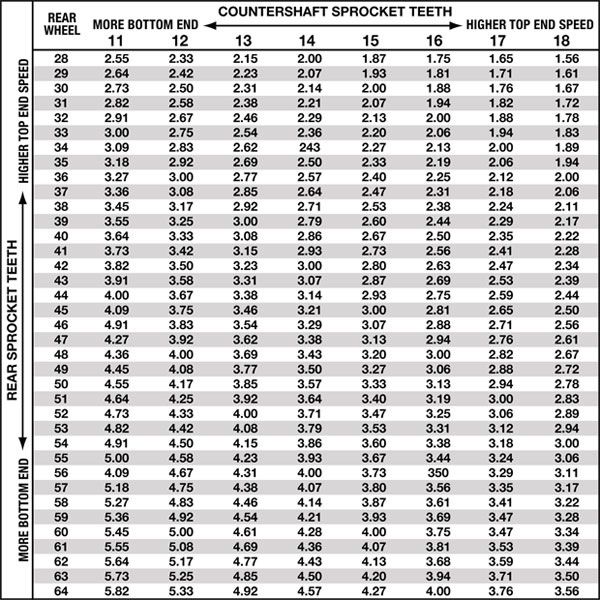

In order to find the gear ratio locate both the number of teeth on the top and the left most column and trace the ratio accordingly. Gear inches is used mostly for comparing one drive train ratio to another and has little physical basis on a bicycle with derailleur. Check the box if the gear is on the same shaft as the gear above it leave it unchecked if the gear meshes with the gear above it.

The gear ratio of the pitch circles of mating gears. See Hobbed Teeth vs Shaved or Ground Teeth below. 60 on the axle divided by 12 on the clutch.

The subscripts 1 and 2 of z 1 and z 2 denote pinion and gear. What is a Gear Ratio on a Go-Kart. Worm Gear Formula Table.

The next steps depend on the state of the planetary gears connected to the carrier although all use the same formula. One of the most common gear ratios for go karts is 11-12 teeth on the clutch sprocket and 60 teeth on the axle sprocket. The driver gears rate of rotation is known.

Gear Engineering and Design Data. N Gear Ratio. For finding size measurement spanning across a fixed number of teeth you can find these measurements using our Gear Span Measurement Calculator and a good set of calipers.

Motorcycle Sprocket SizeRatio Calculator. Ratio 7th Gear. Gear Generator How to Draw Perfect Gears 423 Laser Cut Gears 308 Prototype your gear sets in 2D 119.

T m Torque of Motor lb-in. The gear is the driven output wheel and has the same tooth height and pitch as the pinion. If you state the properties of the pinion and the rotational ratio your gear wheel may be designed fully with no further information assuming it has the same thickness as the pinion.

The ratio of the pitch circles of mating gears defines the speed ratio and the mechanical advantage of the gear set. Electric Scooter Repair Help Modification and Custom Project Help Top Speed and Gear Ratio Calculator. Teeth have gear sprocket e rear sprocket Matchless d80 1933 Hello Rob Lucio wants to know the number of teeth on the two sprockets for a.

Table 42 The Calculations for. If youre using a Schlumpf Drive plus an internal-gear rear hub you should enter the actual number of teeth of the front chainring for the first chainring and this number of teeth times the Schlumpf ratio for the second chainring. For any change in rotation speed the load inertia will reflect back through the gears to the motor.

Top Speed and Gear Ratio Calculator. Measurement Over Pins or Measurement Over Wires is a method for measuring and inspecting spur gears with both even and odd tooth counts. Enter your values as required for module number of teeth pressure angle and ratio.

Includes derailleur gears and internal gear hubs. All calculated values in Table 41 are based upon given module m and number of teeth z 1 and z 2If instead the modulem center distance a and speed ratio i are given then the number of teeth z 1 and z 2 would be calculated using theformulas as shown in Table 42. Motorcycle speed and sprocket calculator with bike database for gearing sprockets tires and chains of over 1750 bikes.

Gear teeth are designed to ensure the pitch circles of engaging gears roll on each other without slipping providing a smooth transmission of rotation from one gear to the next. A 1 to 1 drive. A planetary gear train provides high gear reduction in a compact package.

Features of gears and gear trains include. Links Teeth Needed Help on. Grafischer Ritzelrechner zur Berechnung der Entfaltung von Fahrradschaltungen.

11 Wheel or Axle Sprocket. To find the gear ratio simply divide the axle teeth by the clutch teeth. The ratios are 040 for the Mountain Drive 165 for the Speed Drive and 250 for the High Speed Drive.

2500 Motor Sprocket. Bicycle Gear Inch Calculator Also calculates metres of development and optionally speed or cadence and gain ratio. Where was my singer featherweight made.

SPUR GEAR CALCULATOR - MODULE and DP VERSIONS. Added internal gear support and the ability of positioning the first gear. Gear ratio is determined solely by the number of teeth on each gear.

Get breaking MLB Baseball News our in-depth expert analysis latest rumors and follow your favorite sports leagues and teams with our live updates. Use these equations and calculator to determine the Inertia of a gear drive system. Or when the number of teeth on the chainring and the sprocket are the same.

Enter the wheel size tire size number of chain rings number of teeth select a cassette size and optionally the individual cogs and this tool will help you figure out how much easier or harder your gearing will be if you switch it or buy a new bike with different gearing that your current bike. Number teeth on motor gear. Count the number of teeth on the driver gear.

A simple gear ratio calculator to find the speed and mechanical advantage of a gear system of spur gears. Finally some videos I found on youtube.

Gear Train Gear Ratio Torque And Speed Calculations Smlease Design Gear Train Speed Mechanical Design

Gear Ratio Calculation A 100 Tooth Gear Drives A 25 Tooth Gear Calculate The Gear Ratio Of The Mesh Mechanical Engineering Engineering Mechanical Gears

Calculo De Engranajes Saludos Electricidad Engenheiros Electricidadpty Mechanical Engineering Mechanical Engineering Design Electronic Engineering

Planetary Gear Ratio Calculations Wooden Gear Clock Wooden Gears Gears

Blogger Transmission Automotive Engineering Mechanical Engineering

Pin On Mechanical Design

Planetary Gear Ratio Calculations Boho Dekoru Dis Dekor

Gear Ratio Mechanical Engineering Design Engineering Tools Mechanical Engineering

Adjusting Your Drive Ratio Changing Your Sprockets For Maximum Performance Chaparral Motorsports Motorcycle Gear Motorcycle Ratio

Planetary Gear Ratio Calculations Wooden Gears Gears Milling Machine Projects

Workig Out Gear Ratios Questions Free Energy Projects Gears Energy Projects

Gear Ratio Generally The Gear Ratio Is Calculated By Counting The Teeth Of The Two Gears And Applying The Followin How To Apply Mechanical Design Power

4 Easy Ways To Determine Gear Ratio With Pictures Gears Mechanical Gears Mechanical Design

4 Easy Ways To Determine Gear Ratio With Pictures Gears Mechanical Engineering Design Mechanical Gears

Gears And Gears Ratios Youtube Gears Wooden Clock Automata

Gear Ratio A Simple Calculation Based On Number Of Teeth Gears Wooden Gears Mechanical Engineering Design

Granny Gear Inches Ride Now Save Your Knees For Later Bikepacking Knee Injury Bicycle Gear